Introduction

The Institute of Electrical Machinery and Apparatus (EMA) has been mainly engaging in teaching and scientific research in the fields of electrical machinery, control systems and failure detection since founded in 2001. This institute currently comprises 15 full-time faculties, including 6 professors, 2 associate professors, 6 lecturers and 7 of the people serving as doctoral supervisors. The institute now has 1 Outstanding Dedicator of Beijing Jiaotong University, 1 member of Outstanding 100 Talents Program of Beijing Jiaotong University, 1 Teaching Star of Online Education Center of Ministry of Education, 1 Outstanding Teacher of Beijing municipal and 3 Outstanding Lecturers of the university.

Affiliated to the Electric Traction Engineering Research Center of The Ministry of Education, the EMA Institute serves as the standing director unit of National Technological Innovation Strategic Alliance of amorphous energy saving materials Industry. It has established the Joint Laboratory of High-Speed Railway Bearing Lubrication Technology cooperating with central enterprises such as CRRC and CNPC, and set up the Joint Research Center of Wind Power and Micro Grid and the Intelligent Rail Transit (Electrical) Joint Laboratory with the University of New South Wales.

For the long time, the Institute of Electrical Machinery and Apparatus has been researching in kernel technologies of generator equipments and electric-driven equipments and undertaking a great number of provincial and ministerial projects, such as: the National Key R&D program of China, the Key National International Cooperation Project, the Project of National Important Project on Science (Sub-Project), the National Science and Technology Major Project (Sub-Project), the projects supported by National Natural Science Foundation of China (NSFC), as well as other commissioned projects such as major military projects and enterprise industrialization projects. The institute solves the basic scientific problems of the industry; Meanwhile, it also promotes the technological transformation and upgrading of enterprises and the industrial application of scientific and technological achievements. Its research direction covers civil industries such as power system, rail transit, maglev transportation, electric vehicles and industrial production, military industries such as warship propulsion and auxiliary power, as well as remarkable breakthrough in new materials, new structures and new methodologies.

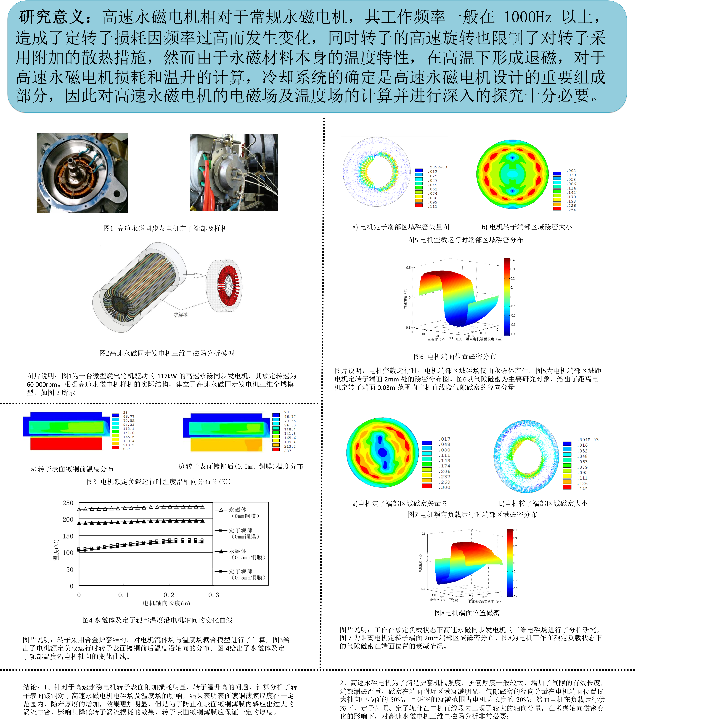

Research Direction

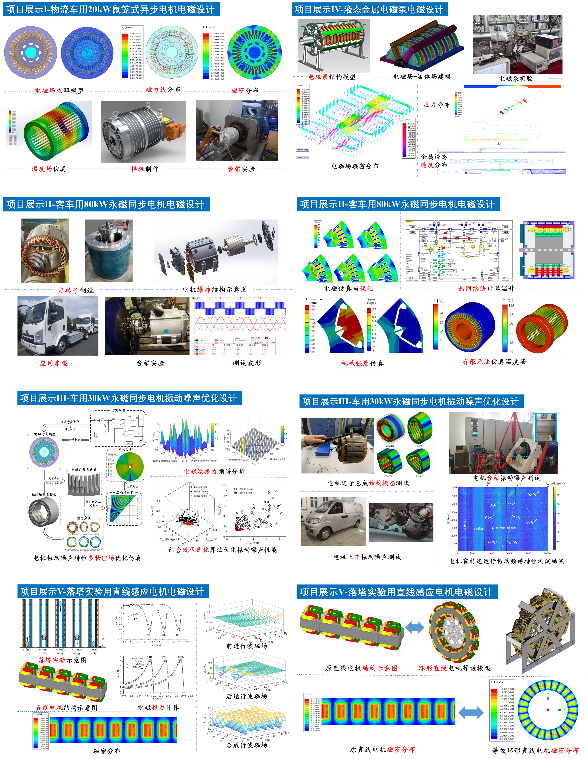

(1) Theoretical research and application of high-end green energy equipments

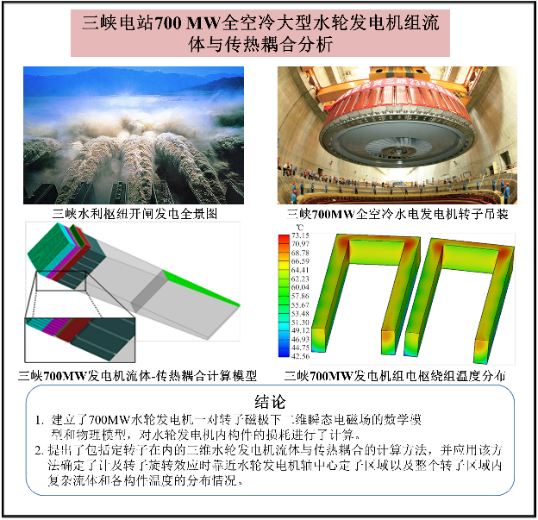

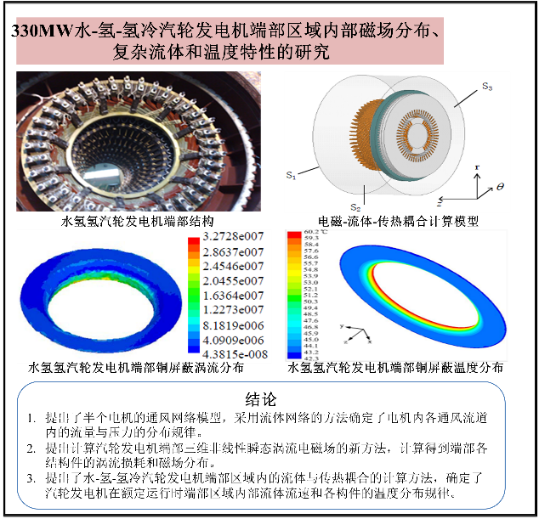

The EMA Institute has carried out research and application of core technologies of high-end power generation equipments in nuclear power, hydro-power, wind power, pumped storage, etc. The achievements, including theoretical innovations and methodological breakthroughs, have solved corresponding bottlenecks and corresponding core research results have get to the international advanced level, which therefore has improved the international competitiveness for the technologies and the products.

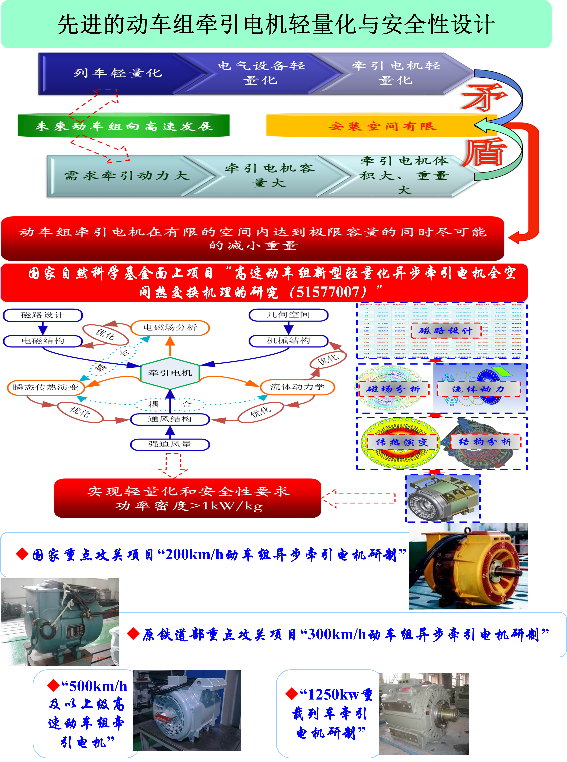

(2) Advanced rail and maglev traffic driving equipment and system of intelligent failure prediction and health management

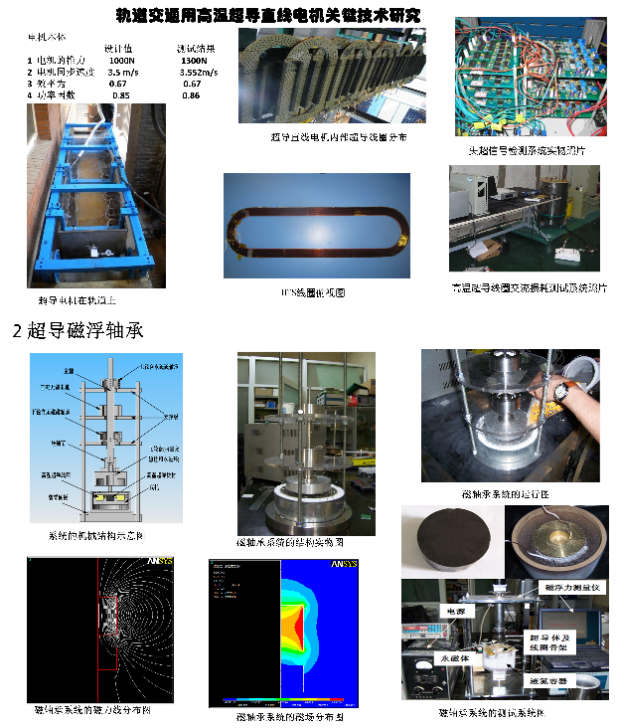

The EMA Institute has been dedicated to theoretical and applied research about lightweight and high-effective design of various types of traction motors for the high speed EMU, including the asynchronous traction motor, the permanent magnet synchronous traction motor, the Maglev linear motor and its control, the superconducting motor and transformer, the switch reluctance machine and the low-speed direct-drive motor. Centering on the problems of railway and Maglev transportation, it overcomes the technical barriers, proceeds in the research frontier and offers economic service to the state and society, as well as making breakthroughs in international joint technological research and development, with its international cooperation influence being enhanced.

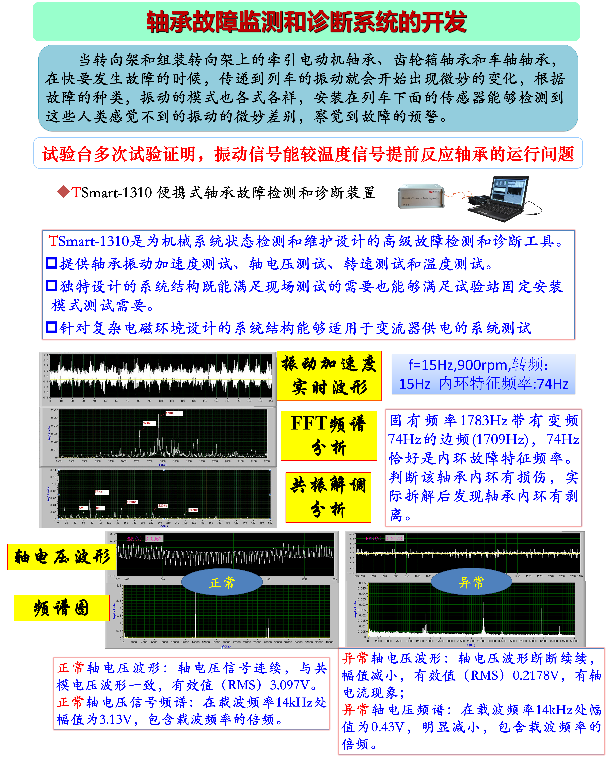

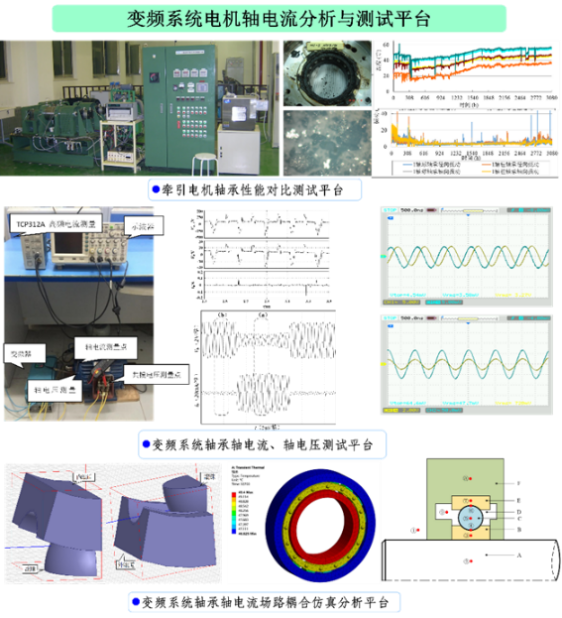

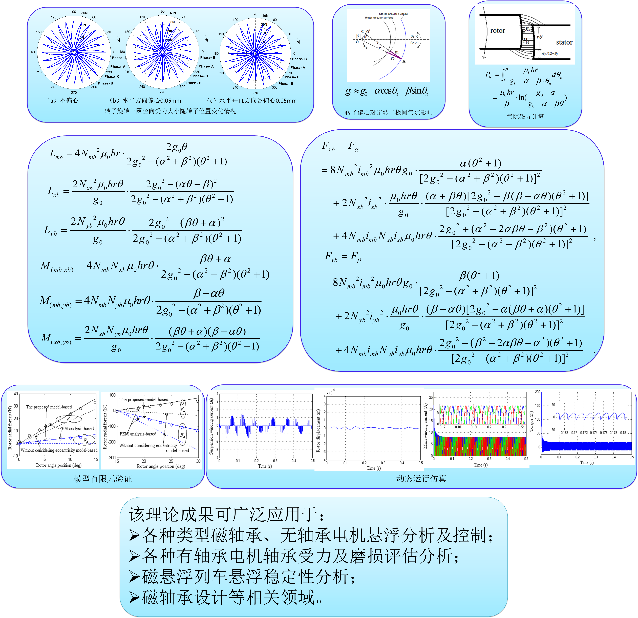

Via the research for key equipment of mechanical transmission system, safe operation of transmission bearing and lubrication, the en-route monitoring and failure diagnosis test platform of electric traction drive system has been founded. As a result, the caution warning of failure category, order of severity & solutions and running safety predication has been successfully realised, which not only satisfied the urgent need of the enterprises, but also assisted in the alternative application of domestic technologies and products.

(3) New materials and its applied technological research and breakthrough

Theoretical research, technical implementation and application have been executed by the EMA Institute on wide range of new materials and novel technologies, such as: superconducting materials, amorphous alloy materials, new alloy electric material, ceramic bearing, Maglev bearing, insulated bearing, nano coating, high-heat conductive material in highly efficient and energy-saving new type motors with high power density and high rotating speed. Hence, a platform of the advanced design and transformation has been constructed in the field of special types of electrical machines in China

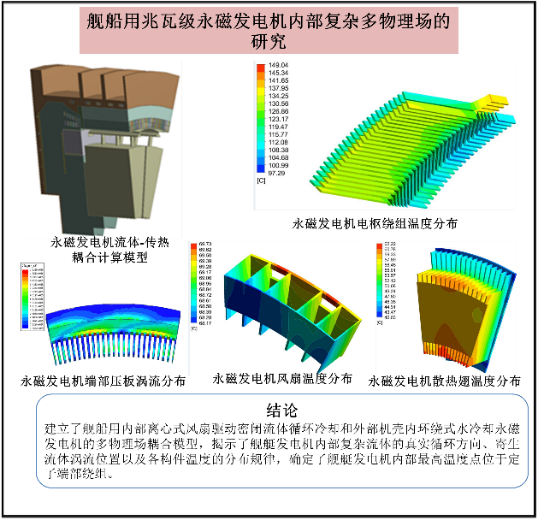

(4)Research on Driving Equipment of Military Utilisation and New Energy Vehicles

Aiming at military and civil applications such as aerospace, navy, land combat vehicles and electric vehicles, the EMA Institute has carried out theoretical and industrial research on novel permanent magnet drive motors, electromagnetic propulsion systems and servo drive systems. Key technical indicators has reached the international leading level, which helps to promote the technical upgrade and application of all-electric drive systems.

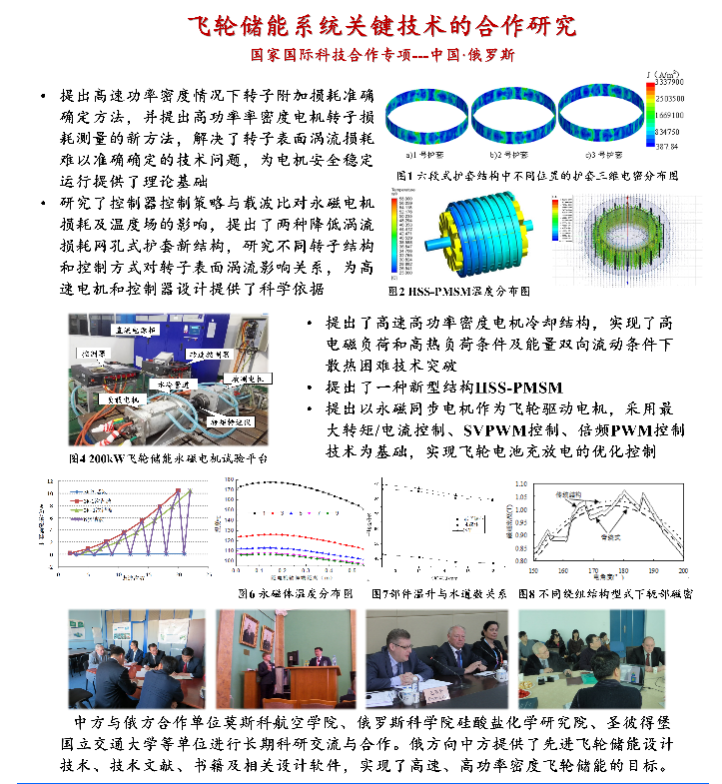

Integrated research on electrical machines and drive technology has been carried out to meet the high-power, high-density, high-speed and high-torque requirements, in which the transformation and the application of technical achievements have been completed, and the level of technological innovation and R&D platform of enterprises has been enhanced.

The institute also conducted the technological and applied research on energy storage equipment and control system, realized the key technology breakthrough and innovation of flywheel energy storage system.

Representative Results

The EMA Institute currently has 1 person enjoying special grant from The State Council, 1 international Leading Talent of the Royal New Zealand Academy of Sciences, and 1 IET Fellow. More than 500 academic papers and more than 350 SCI and EI papers have been published, among which more than 20 papers were published on IEEE Transactions on Industrial Electronics (An1) and more than 20 papers were included in high power impact factor ESI. It has got over 150 invention patents, won 1 first prize of provincial Invention, 1 first prize of Science and Technology Progress of Ministry of Education, 6 second prize of provincial level and 4 third prize.

(1)Cooperated with three famous Chinese power groups, it has carried out a large number of basic theoretic and applied researches on large generators key technology, overcome multiple technological problems of air-cooled turbonator, water-turbine generator of super large capacity, nuclear-powered turbonator of super large capacity and pumped power storage and generation, broke the technological monopoly of famous foreign transnational corporations such as Siemens, Westinghouse. The relevant research results have been successfully applied to various power stations at home and abroad, providing strong technical support for the practice, research, development and international competitiveness of new products. The research achievements have reached the international leading level, with 1 first prize and 1 second prize of provincial Technical invention.

(2)To solve the difficulty in higher efficiency and lightweight for traction motor, a piles of key technologies, consisting of the selection of electromagnetic performances and energy efficiency, the optimization of cooling and lightweight design, the operation considering both the structure, the safety and noise reduction, etc. Collaborative optimization method with multi-algorithm fusion and multi field analysis has been proposed. Corresponding achievements and the efficiency indicators of products have both reached the international advanced level. The industrial application has been successfully realized. In the past five years, 186,000 units of products obtained from this research have been produced, with the sales revenue of 2.06 billion RMB and the foreign exchange of 158 million US dollars earned from export. 1 first prize of Science and Technology Progress of Ministry of Education, 2 second prize of provincial level, 2 third prize have been awarded and 2 patent have been transformed into industrial achievements.